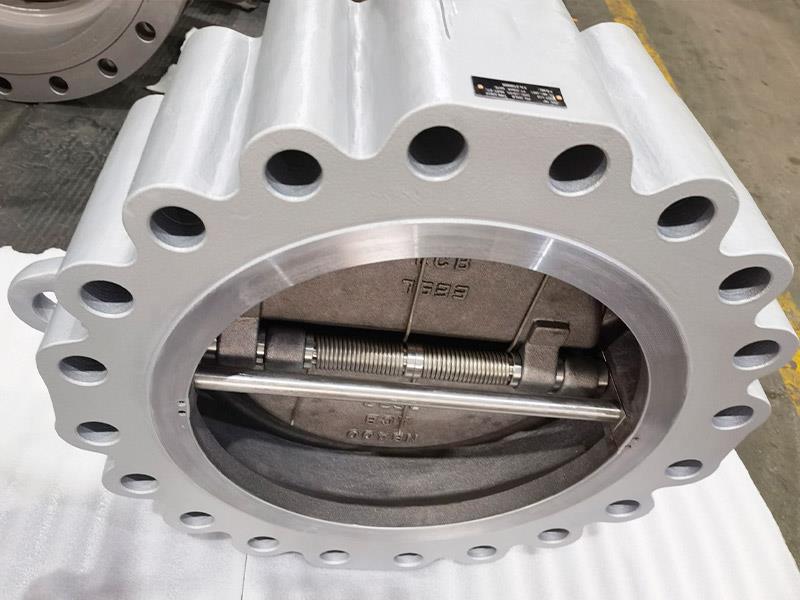

The center vertical pin shaft. When the valve is open, the resultant force of fluid is on the center of sealing face of valve clack, while the point of action of counter spring support force is on the center of valve clack surface so that the root of valve clack opens firstly. It avoids wearing of sealing face of old conventional valve when valve opens, and increase the persistence of valve seal. When flow slows down, counter force of torsion spring makes the valve clack moves to valve seat, and the valve is in slow off stage. When fluid flow backwards, the closing of valve clack is correspondingly increased and enters the rapid closing stage under force of back flow fluid on valve clack and reaction force of torsion spring. The influence and harm of water hammer is effectively reduced. When closed, the spring force closes the top of valve clack firstly so that bite phenomenon on root of valve clack is prevented to guarantee longer service life of valve sealing face.

Design Feature:

-End Type: wafer, wafer plug, wafer flange

-Disc Type: Double disc or Single disc

-Light in weight and short in face to face dimension compared with traditional check valve; the disc closes quickly with less water hammer pressure